How do Formance SIPs join?

Formance panels are a high-performance building envelope solution that combines structure and insulation. Here's a comprehensive guide on how these panels are fixed together, making your construction project efficient and robust.

Joining Methods for Formance Panels

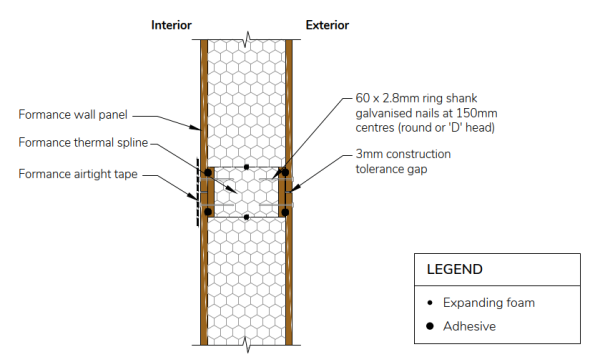

Thermal (SIP) Spline

Advantage: Reduces thermal bridging.

Method:

- Apply a continuous bead of adhesive on each side of the panel rebate.

- Add a line of expanding foam to the EPS core at the bottom.

- Insert the thermal spline into the rebate.

- Secure the panels with galvanized nails at 150mm centers.

- Apply Formance airtight tape over the join for a secure seal.

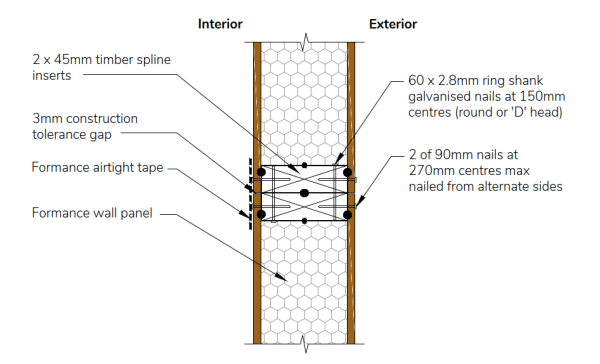

Timber Spline

Advantage: Ideal for wall and roof panels.

Method:

- Glue and nail double 45mm timber splines together.

- Insert them into the panel rebate.

- Secure with nails and apply airtight tape over the joint.

Connecting Formance Panels at Corners

External Corners

- Use 45mm timber inserts.

- Secure with galvanized nails at 150mm centers and Formance SIP screws at 300mm centers.

- Ensure screws penetrate at least 40mm into the timber.

- Apply Formance airtight tape for a continuous seal.

Internal Corners

- Follow a similar process as external corners.

- Washers on SIP screws can be omitted for a flush surface.

- Ensure screws are flush with the OSB skin and not overtightened.

Roof Panels to Wall Connection

Method:

- Apply adhesive and expanding foam to the rebates of roof and wall panels.

- Insert the timber spline into the panel rebates.

- Secure with nails and Formance SIP screws at 300mm centers.

- Use Formance airtight tape at the junction for airtightness.

Installation Tips

Adhesive and Foam: Always use Formance PU expanding foam and adhesive, both EPS compatible.

Nails and Screws: Use 60 x 2.8mm ring shank galvanized nails and 10g Formance SIP screws for additional strength.

Airtightness: Ensure all junctions and joints are airtight using Formance airtight tape. Continuous glue and foam beads are crucial.

Handling: Store panels flat, avoid significant impacts, and plan installation sequences to minimize handling.

Download the full installation guide here.

Detailed Installation Steps

By following these guidelines, you can ensure that Formance panels are properly joined, resulting in a strong and thermally efficient building envelope. This methodical approach ensures a seamless and airtight structure, enhancing both the strength and energy efficiency of the building. For more detailed information, refer to the Formance Design Guide and Installation Guide, or contact the Formance team for specific project advice.