How Durable Are Structural Insulated Panels (SIPs)? A Look at EPS and OSB in Long-Term Home Construction

More than 95% of all SIPs in North America are made using the tried and true combination of OSB and EPS. So what makes this such a popular choice, and why has it stood the test of time?

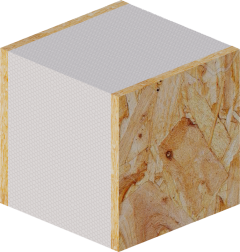

Structural Insulated Panels (SIPs) are a popular choice for building energy-efficient homes, using Expanded Polystyrene (EPS) insulation and Oriented Strand Board (OSB) facings. This article explores the durability of both materials and explains why SIPs are a long-lasting solution for modern home construction.

OSB and EPS SIP

Durability of EPS in SIPs

Expanded Polystyrene (EPS) is widely used as the core insulation in SIPs due to its impressive durability and thermal performance.

-

Inherent Material Durability:

EPS is a closed-cell thermoplastic material that is highly resistant to moisture and air infiltration. It doesn't degrade or absorb water, which means it remains effective as an insulator for decades. The rigidity of EPS also ensures it retains its shape without settling or breaking down over time. -

Protection by the SIP Panel:

Inside the SIP, EPS is protected by OSB facings and the surrounding building envelope. This shielding prevents direct exposure to environmental factors like UV rays, mechanical wear, and extreme temperatures, further preserving the EPS core. -

Low Reactivity and Stability:

EPS is chemically inert, meaning it doesn’t react with other materials, ensuring it won’t break down over time. Its closed-cell structure keeps it dimensionally stable, preventing shrinkage or warping, which is critical for long-term performance. -

Moisture Resistance:

The closed-cell structure of EPS makes it resistant to moisture absorption. When combined with appropriate weatherproofing and internal moisture control in the SIP system, EPS remains dry and free from mold or rot. -

No Biological Attack:

EPS is not a food source for pests or fungi, so it's not prone to biological degradation. As long as the SIP system is properly sealed, there is no risk of organic decay affecting EPS.

Durability of OSB in SIPs

Oriented Strand Board (OSB) is used as the structural facing in SIPs and plays a crucial role in the panel's overall strength and longevity.

-

Material Strength:

OSB is an engineered wood product known for its structural integrity and load-bearing capacity. In SIPs, OSB adds significant strength, allowing the panel to handle both compressive and tensile forces. When installed properly, OSB remains structurally sound indefinitely. -

Protection by the SIP System:

As part of the SIP, OSB is protected from direct exposure to the elements by cladding, flashing, and other weatherproofing measures. This prevents water penetration and ensures the OSB doesn’t experience swelling, warping, or rotting. -

Moisture Management:

Though wood-based, OSB in a SIP system is protected by the building’s weatherproofing and vapor barriers. With appropriate detailing, such as proper sealing and flashing, moisture intrusion is prevented. Additionally, the adhesives used in OSB provide moderate resistance to water, further enhancing its durability. -

Biological Resistance with Proper Installation:

In normal residential conditions and when properly installed with weatherproofing, OSB is shielded from risks like mold or termite damage. Internal moisture control systems, including ventilation and vapor barriers, keep OSB dry and protected, ensuring that biological threats are not an issue. -

Dimensional Stability:

OSB is engineered to resist warping or shrinking when exposed to normal environmental fluctuations. This dimensional stability is crucial for ensuring the long-term performance of SIPs, especially in climates where temperature and humidity vary.

In closing

When combining the durability of both EPS and OSB, SIPs are an excellent choice for long-term, energy-efficient construction. EPS offers excellent moisture resistance, chemical stability, and long-lasting insulation performance, while OSB provides the necessary structural strength and rigidity to ensure the panel's longevity. When properly installed with the right weatherproofing and internal moisture controls, SIPs can easily last the lifetime of the building.

For homeowners looking to invest in durable, low-maintenance, and sustainable construction, SIPs present a robust solution that will continue to perform for decades.

Some additional references.

-

Structural Insulated Panel Association (SIPA) – A leading authority on SIP construction, SIPA provides detailed information on the overall durability, energy efficiency, and benefits of using Structural Insulated Panels in modern homes.

- Building Research Association of New Zealand (BRANZ) – BRANZ is a trusted research organization in New Zealand that evaluates building materials, including SIPs. Their research provides a reliable understanding of the longevity and performance of SIP panels in construction. www.branz.co.nz

These references offer further insights and validate the durability and reliability of SIPs, supporting their use as a long-term solution in modern construction.