Freezer Panels vs SIPs - what's the difference?

Freezer Panels vs SIPs: The Real Difference in Insulated Building Panels

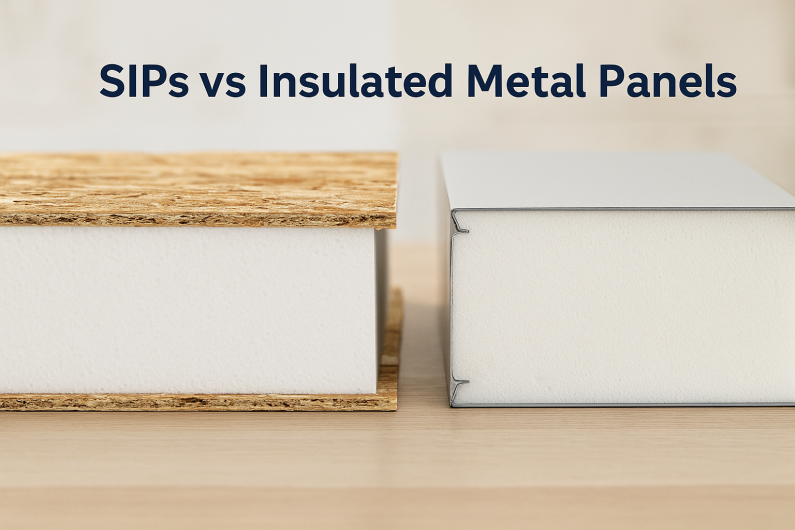

If you’ve heard someone say, “SIPs are just freezer panels”—they’re not alone. In New Zealand, the term “freezer panel” is commonly used to describe all sorts of sandwich panel systems. But that assumption blurs a vital distinction in modern building technology.

So, let’s get clear on what Structural Insulated Panels (SIPs) really are, how they differ from freezer panels (also known as Insulated Metal Panels or IMPs), and why it matters for your next building project.

What is a Structural Insulated Panel (SIP)?

A SIP is a high-performance composite building panel that replaces traditional timber framing and insulation. A SIP consists of:

-

A rigid insulation core (usually Expanded Polystyrene or EPS)

-

Two structural outer layers (typically Oriented Strand Board – OSB)

This creates a panel that is both load-bearing and highly insulating. SIPs are used for walls, roofs, and floors in residential and light commercial buildings, including schools, homes, apartments, and retirement villages.

SIPs form a complete thermal envelope, drastically reducing air leakage, improving indoor comfort, and cutting energy bills. And when you’re using a trusted system like Formance SIPs, you’re building with a product that’s CodeMark certified and proven in New Zealand conditions.

What is a Freezer Panel (Insulated Metal Panel)?

Freezer panels, the common name for Insulated Metal Panels (IMPs) are designed for a very different purpose. These panels consist of a rigid foam core (EPS, PIR, or PUR), laminated between metal skins (typically steel or aluminium). They’re widely used in:

-

Cold storage rooms

-

Food processing plants

-

Packhouses

-

Agricultural buildings

Their purpose? To control temperature efficiently. Their limitation? They’re not structural.

SIPs vs Freezer Panels: Key Differences

| Feature | SIPs (Structural Insulated Panels) | Freezer Panels (IMPs) |

|---|---|---|

| Structural Capacity | Fully structural (walls, roofs, floors) | Non-structural, not load-bearing |

| Typical Use | Residential & commercial buildings | Coolstores, freezers, industrial cladding |

| Skins | OSB (engineered timber board) | Steel or aluminium sheets |

| Compliance | CodeMark certified, meets NZBC clauses B1, B2, H1, etc. | Not intended for Code-compliant primary structure |

| Fire Performance | Flame-retardant EPS, encapsulated and tested | Metal skins conduct heat; core can liquefy |

| Connections | Nailed, glued, solid timber trims | Riveted or folded metal junctions |

| Thermal Bridging | Very low – minimal interruptions in insulation layer | Moderate – metal joints can create cold paths |

| Seismic Performance | Tested to NZ standards, high racking strength | Not intended for seismic structural use |

| Recladding | SIP buildings can be reclad multiple times | Cannot be reclad as it's part of the panel |

Key Maintenance Difference: Lifespan and Replaceability

One of the most overlooked but critical differences between SIPs and freezer panels is in long-term maintenance.

-

SIPs are designed with separate cladding layers. The external cladding (whether it’s weatherboard, metal roofing, or fibre cement) is installed over the SIP and can be replaced or upgraded independently once it reaches the end of its life.

-

Freezer panels are the cladding. The outer metal skin is permanently bonded to the insulation core. When that metal corrodes, dents, or reaches end of life (typically 20–25 years), the entire panel system must be replaced. That means more cost, more waste, and more disruption.

For asset owners and developers, this is a major cost differentiator over the lifecycle of the building.

Why the Confusion?

The confusion comes down to appearance. Both SIPs and freezer panels are “sandwich panels” made of a foam core between two skins. But the application and performance are dramatically different.

It’s like comparing laminated benchtops and engineered stone—both are flat and functional, but the substance, strength, and lifespan are not the same.

A Better Building Solution

If you’re building homes, apartments, schools, or retirement villages, freezer panels simply aren’t the right choice. They’re not designed for structural load, they have limitations in fire safety, and replacement is all-or-nothing.

By contrast, Formance SIPs offer:

-

Code-compliant structural integrity

-

Superior thermal and seismic performance

-

Flexible design options

-

Lower maintenance costs over the building lifecycle

-

A warm, dry, airtight indoor environment

Keywords at a Glance

Here’s what builders, architects, and specifiers are searching for:

-

“freezer panels for walls”

-

“structural insulated panels NZ”

-

“SIPs vs insulated metal panels”

-

“high performance wall panels”

-

“best building insulation system”

-

“pre-insulated roof panels vs SIPs”

-

“cold storage panels for houses” (mistakenly!)

This article helps guide those searchers to the right place: Formance SIPs, the smarter choice for better buildings.

Final Word

Freezer panels have their place—in temperature-controlled environments. But if you’re building a home or structure that needs to stand the test of time, Formance SIPs deliver strength, safety, efficiency, and long-term value.

They're not the same product. And once you understand the difference, it’s clear which one belongs in a house.

Talk to us today to learn how Formance SIPs can improve the performance and longevity of your next building project.