What insulation has the least Co2?

What’s your ROI on Co2?

When choosing insulation materials in your new home and considering the carbon impact of those materials, it’s important to look at the two main types of carbon, embodied and operational. Embodied carbon is how much carbon has been used to make the product, and operation carbon is how much it will use going forward. Energy efficient homes have lower embodied carbon due to less energy being consumed to keep the home warm in winter and cool in summer.

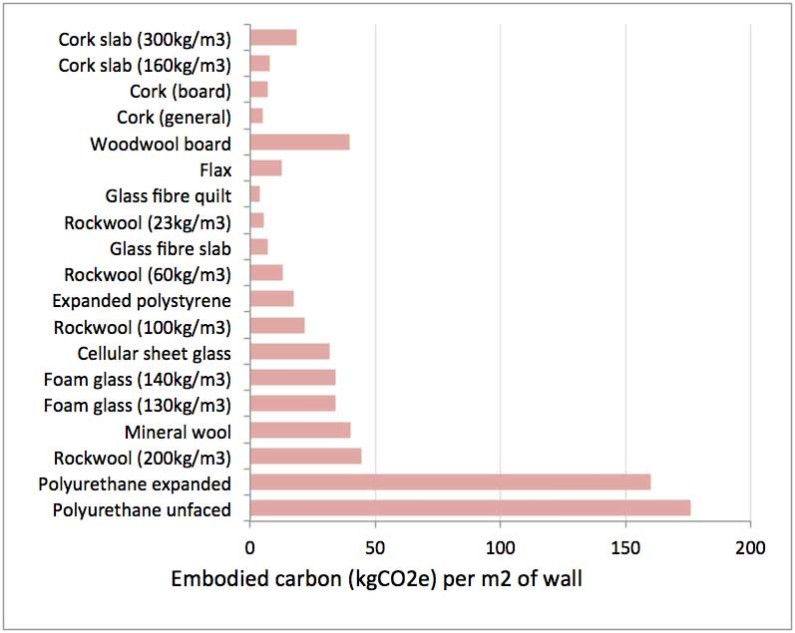

Greenspec's recent study on embodied carbon in insulation provides valuable insights into the different thickness requirements for each common insulation material.

We’re often asked why we use EPS in our structural insulated panels, and having low embodied carbon is one of the reasons. It shows that EPS has a lower embodied carbon footprint than a lot of mainstream materials even when factoring in the different thicknesses required to achieve the same insulation value (R value).

If you consider the return on carbon invested, EPS has an approximately 35 times higher ROI than PUR, for example. This means that you could build 35 houses with EPS insulation using the same amount of embodied carbon as 1 house built with PUR insulation.

EPS is also fully recyclable, making it an environmentally friendly choice.

Although there are some other materials that are lower in embodied carbon, EPS is our favored choice as it’s the most cost effective and comes in sheets that can be optimized for different projects, meaning little waste.

Contact Formance to learn how SIPs can help assist in your project.

Reference:

https://www.greenspec.co.uk/building-design/embodied-carbon-of-insulation/