3 - Certified Passive Houses with SIPs

With the growing awareness in New Zealand of the benefits of highly energy-efficient, comfortable, and healthy homes, Certified Passive Houses are becoming more popular. This bulletin supports Designers using Formance panels in the Passive House project.

The values provided on the Formance website are for an overall wall assembly with air surface film resistance and cavities. These cannot be entered into PHPP directly.

The values in Table 1 below can be used to calculate the SIP construction performance using the thermal conductivities and thicknesses in the table. Note the OSB thickness and conductivity must be used along with the EPS thicknesses to be accurate.

In Passive House design using Formance SIPs it is common to use an internal service cavity. This is often insulated with fibre insulation to increase the overall construction thermal performance.

Test data provided by the manufacturer for panel testing was completed in NZ meeting the NZBC requirements for foam insulation. Thermal conductivity was for a measured 165mm panel with OSB skins. This is documented in Report NZWTA

No. 1231866.3R and testing conducted per ASTM C518 Steady-state thermal transmission by heat flow. Note that the SIP manufacturer controls the core EPS density to minimum 20 kg/m3. Defining the OSB skins to be 11mm thick with a thermal conductivity of 0.13 W/(mK) results in an EPS thermal conductivity of 0.038 W/(mK).

Timber fraction in the SIP panel must be accounted for either in the overall U-value via a % timber or as a thermal bridging calculation (PSI value). SIP Insulated Splines can be considered thermal bridge free and neglected from the timber fraction.

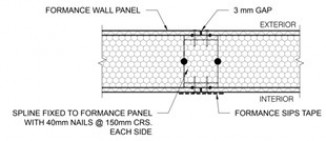

Figure 1: Formance Insulated Spline.

Timber Splines and additional timber lintels and beams are NOT thermal bridge free and will need to be considered as either a timber fraction on the U-values sheet or as a Thermal Bridge calculation. We recommend using a conservative timber content in the panels to prevent being surprised by the performance loss due to the timber. As timber is 3.5 times more conductive than the EPS core it can have a significant effect.

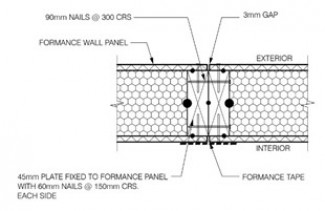

Figure 2: Formance Timber Spline. If the wall of roof panel has these at every junction that would be a minimum of 7.5% timber

Example U-value calculations for SIP panels accounting for timber content in the overall U-value are shown below.

Any steel in the SIP layer has an even larger impact than the timber content and requires a detailed thermal bridge calculation unless the steel is fully inside the building (not in the insulation layer) or fully outside the building.

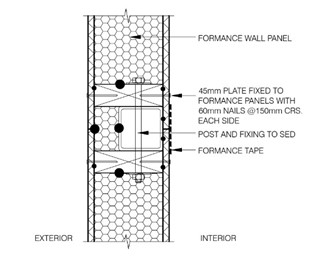

Figure 3: Steel Post in SIP per Special Engineering Design. Thermal bridge calculation will be required. Note the steel post is to the interior which is good practice.

Figure 4: Detailed thermal bridge calculation showing SIP spline has PSI value less than 0.01 W/(mK) and may be neglected in Passive House Certification.

Figure 5: 'Perfect' SIP wall 165mm panel with ZERO timber content. This is not realistic unless all joints use Insulated

splines and lintels etc. are accounted for in thermal bridge calculations at window installs etc.

Figure 6: SIP wall panel with high but realistic timber content. Notice it is 15% worse than the 'perfect' SIP wall

above.

Want to discuss your project? Get in touch here.

Looking for a builder? Check out our build partners around the country

References

Formance SIP Performance for use in Certified Passive House Projects – Jason E. Quinn CMEngNZ IntPE(USA). Sustainable Engineering Ltd. September 2020.